A Furnace for Firing Ceramic Products Is Called

US20060108347A1 US11313757 US31375705A US2006108347A1 US 20060108347 A1 US20060108347 A1 US 20060108347A1 US 31375705 A US31375705 A US 31375705A US 2006108347 A1 US2006108347 A1 US 2006108347A1 Authority US United States Prior art keywords firing furnace heat generation power supply ceramic Prior art date 2004-08-06 Legal. Lithium disilicate is distinguished by its high strength and in addition to processing with CADCAM systems can be pressed just like classic ceramics and it is for this characteristic that it is increasingly used in the manufacture of prostheses.

Pottery Ceramics Stoneware And Porcelain A Brief Explanation Nom Living

Ovens and furnaces for firing cement glass or chemical products.

. Each heating element is manufactured by applying pressure entirely to. Firing clay is when a clay is fired in a kiln this is to make the clay stay strong. The ring-like base of a ceramic piece usually heavier than the surrounding body.

Remotely controlled undersea cameras and other manned devices also use technical ceramics that require high-fire furnaces. The furnace is also used for firing ceramic products and sterilizing medical instruments. The Reverberatory type Coal Fired Grate Furnaces have bridge wall over which the flame sweeps into the furnace hearth.

At 1922F 1050C needle shaped crystals of mullite 3Al2O32SiO2 begin to form giving the fired clay strength and hardness. Go up to Chapter 84. At 1832F 1000C the clay crystals begin to break down and melt.

The assay furnace is equipped with an integrated. A combination furnace should include programs for firing a range of dental ceramic materials as well as the ability to create customized programs to meet the needs of any lab. The heat from the furnace has been measured by means of thermocouples and has been.

An electric or gas furnace for firing ceramic products. With a foundation history back in 1996 today with 2500 m2 factory area we are placed as one of the leading manufacturer and global supplier of industrial furnaces and firing plants for. Each heating element is formed of a material containing irregularly oriented crystal grains.

These sensors are typically base-metal or rare-metal and are designed to withstand high temperatures for example as high as 1000 C to 1600 C found in a kiln chamber. This long furnace is subdivided in to four zones. Pottery which has not been bisque fired.

An electrical furnace firing the ceramic products has been designed and its automatic control has been implemented. Yes any pottery and ceramic. The information in our platform is also available via an API or via an Excel upload-download routine called ABC Automatic Batch Control.

These furnaces are especially used for the assay of precious metals and ashing processes where the insulation and heating must be protected from emerging gasses and vapours. Our temperature sensors are used for monitoring the temperature in kilns ovens or furnaces when firing green ceramics to form sintered ceramics are called thermocouples. The discs are fired to 3100F 1700C to form a hard and extremely dense fired ceramic component that is used in the communication field for cellular telephone towers around the world.

Accuracy of firing temperature preheatingcooling and other stages of ceramic firing are vital to a life like looking restoration. First zone is called drying zone where the temperature is maintained at around 150C to remove moisture from the green ceramic insulator. A firing furnace includes a housing having a firing chamber for receiving a firing subject and a plurality of heating elements for generating heat when supplied with current to heat the firing subject in the firing chamber.

A firing cycle to the temp at which the glaze materials will melt to form a glass-like coating. Furnace used for the production of ceramic insulator has long tunnel shaped structure as shown in Fig. When mullite forms from metakaolin Al2O32SiO2 extra free silica is released.

The fired clay is known as metakaolin. Kiln-fired glass or warm glass as it is also called is typically done in an electric kiln at temperatures lower than ceramic temperatures. Ovens and furnaces for firing ceramic products.

The inner chamber is designed so that uniform heating of the entire working area is created. Within the 750 1200 price range Soul Ceramics offers the Evenheat High Fire 1210B for 113999 and the Jen-Ken AF3C 119 for 90799. Our Porcelain furnaces also called ceramic ovens are made of quality materials built to last.

For reference Cone 04 is about 1900 degrees F and Cone 10 is about 2350. Soul Ceramics guarantees the lowest prices available with kilns ranging from just over 300 to close to 5000. Because of the lower temperatures involved all ceramic kilns are capable of firing glass.

Other furnace designs call for flat flame burners firing on either side of a center wall or firing across the floor to a center dividing wall. A similar principle is applied in the so-called Elevator Furnaces. To address this problem a proposed project aimed to compare the resultant strength values exhibited by ceramic mold samples of various firing histories to quantify the.

Furnace is generally used for firing heavy or bulky shaped bricks. All of our ceramic furnaces are programmable to suit all types of ceramic porcelain firings. Furnace 100x50x50 cm may be used to fire even small ceramic products such as trinkets PLC has been used for the automation of the system.

A furnace made of refractory clay materials for firing ceramic products. In the early days these enameling furnaces were made of refractory bricks due to the required firing temperature between 800 and 850 degrees Celsius. This ensures that all parts processed in one step are in the same conditions.

Furnaces for firing and pressing ceramic. Kiln wash A mixture usually flint or kaolin which is brushed on kiln shelves to prevent glaze from adhering. The press functions of these furnaces use a combination of temperature and pressure in order to press ceramic materials into the proper restoration design.

1300-1500 degrees F is typical. Second zone is called baking zone with temperature around. Curing or firing a porcelain vitreous enameling coating is done in high temperature enameling furnaces.

Consistently result in ceramic mold strengths within this range is not readily available. Does ceramic shrink when it dries. The furnace chamber forms a ceramic muffle which can easily be replaced.

However such bricks are sensitive for thermal shocks and need to be. A typical example of wall-fired flat flame burners is the double fired coil design used in ethylene furnaces and some coker furnaces.

Large Scheurich German Ceramic Art Pottery Floor Vase Mid Century Modern Palm Beach Boho Chic Brutalist Umbrella Sta Pottery Art Pottery Vase Porcelain Decor

Pottery Drying Turning And Firing Britannica

Oppede Pottery Pottery Lamp Pottery Lamp

Ceramics Vocabulary Words Flashcards Quizlet

What Is Clay Called After It Is Fired Quora

Prometheus Pre Programmed Mini Kiln Pro 1 Prg Kiln Metal Clay Metal Jewelry Making

The Community Of Potters Issuu

Blue Tile Porcelain Earrings Oval Ceramic Earrings Blue Drop Etsy Porcelain Earrings Polymer Clay Earrings Triangle Accessories

You May Have Heard Of Crackle Glaze Or Also Called Crazing This Does Involve A Specific Technique But There Are A Few Ch Crackle Glaze Pottery Studio Glaze

Painting Ceramics With Acrylic Paint A Guide To Painting Ceramics

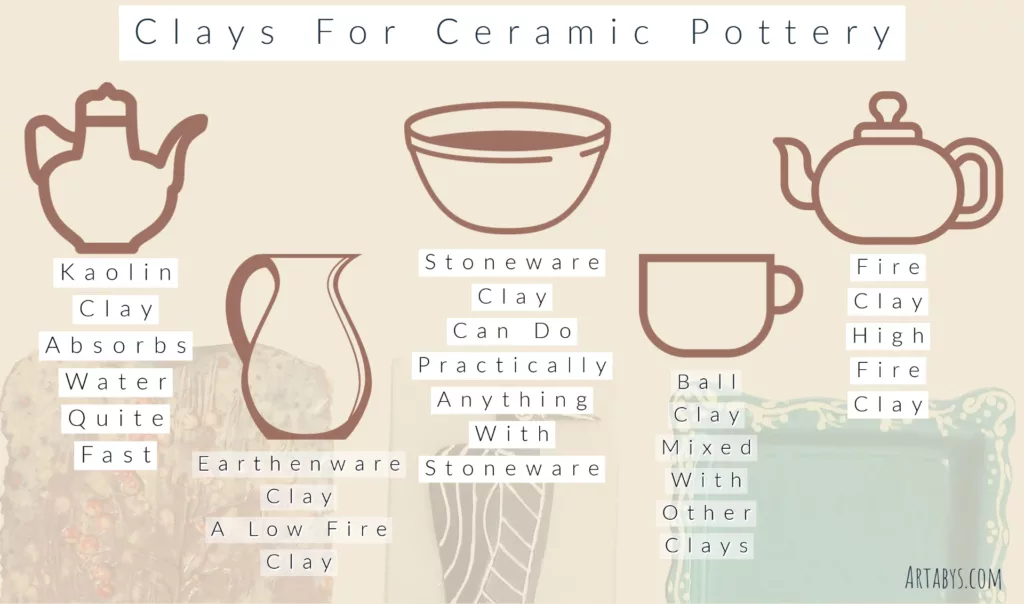

What Clay Do You Need For Ceramic Pottery Artabys

What Are The Four Types Of Clay Beginner Pottery Slab Pottery Handmade Ceramics

Ceramic Kiln High Resolution Stock Photography And Images Alamy

Refractory Brick Production Site Refractory Brick Bricks For Sale Insulation Materials

Guide To Kiln Temperature Ranges For Pottery Soul Ceramics

Heritage Free Full Text On Site Identification Of Pottery With Pxrf An Example Of European And Chinese Red Stonewares Html

Comments

Post a Comment